How efficient is activated carbon in wastewater treatment?

Time : 2025-12-08

Wastewater treatment is a critical process for protecting the environment and human health and activated carbon has long been a reliable ally in this field. Many industries and municipalities rely on activated carbon for wastewater treatment because of its strong adsorption capacity to remove pollutants odors and harmful substances. But just how efficient is it and what factors affect its performance? This article will break down the efficiency of activated carbon in wastewater treatment share real world cases and explain how to maximize its effectiveness for different types of wastewater.

Why Activated Carbon Excels in Wastewater Treatment

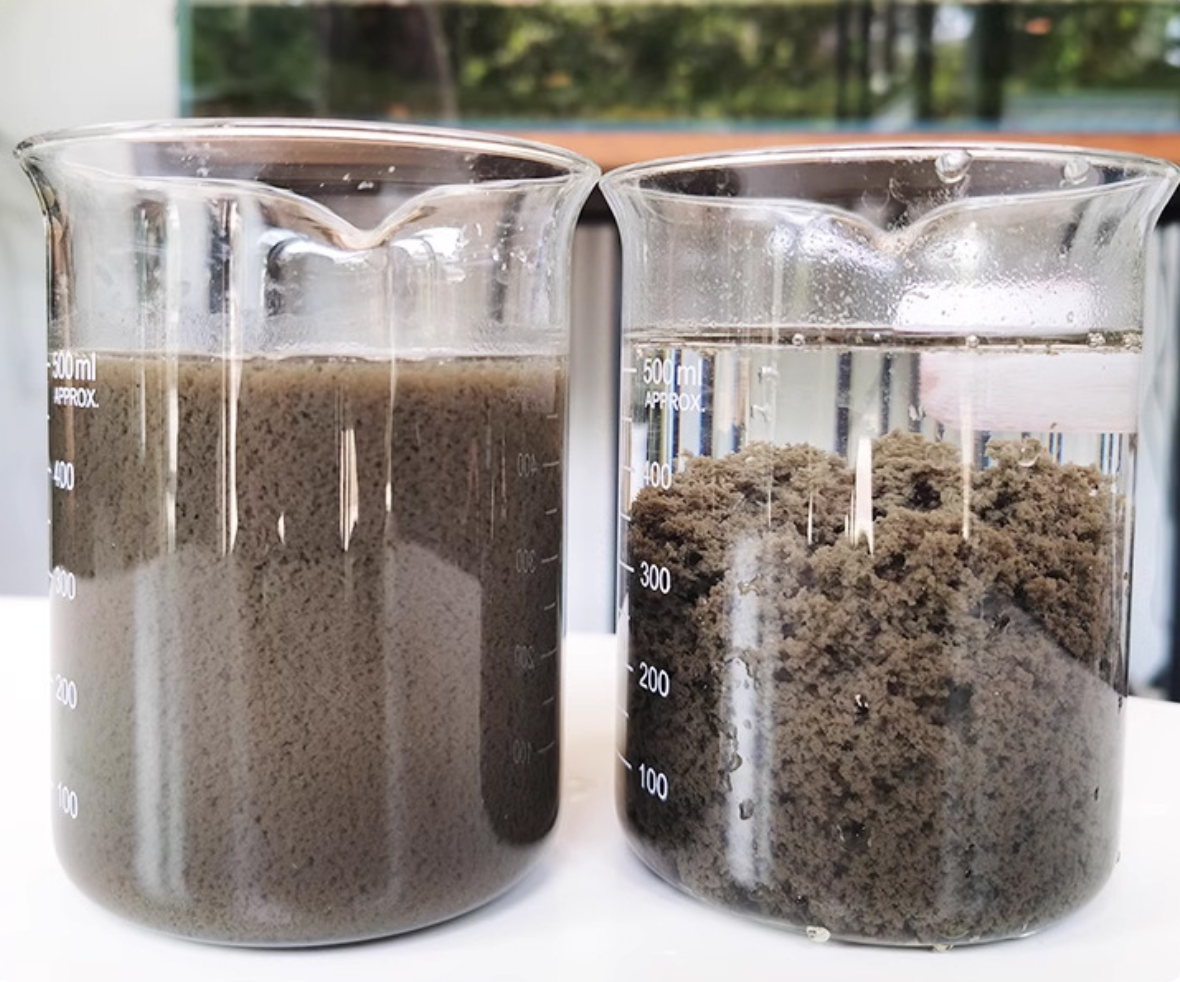

Activated carbon’s efficiency in wastewater treatment comes from its unique structure. With a huge surface area filled with tiny pores it can trap a wide range of pollutants including organic compounds heavy metals and dyes through adsorption. Unlike some chemical treatments it works without producing harmful byproducts making it environmentally friendly. For wastewater treatment the type of activated carbon matters a lot. Powder activated carbon is perfect for decolorization and purification tasks such as treating textile or food processing wastewater. It mixes easily with water and quickly adsorbs colored impurities and organic pollutants. Granular activated carbon on the other hand is ideal for long term filtration systems like municipal wastewater treatment plants. It maintains its structure well allowing water to flow through while continuously removing contaminants. A textile factory in China once used powder activated carbon for wastewater treatment and saw a 95% reduction in dye concentration meeting national discharge standards easily.

Key Factors Influencing Efficiency in Wastewater Treatment

Several factors determine how efficient activated carbon is in wastewater treatment. First the type and concentration of pollutants. Organic pollutants like phenols and dyes are easily adsorbed but heavy metals may require specialized activated carbon with modified surfaces. A food processing plant found that using coconut shell granular activated carbon reduced organic matter in its wastewater by 88% but needed a combination of activated carbon and other treatments for heavy metal removal. Second the pH and temperature of the wastewater. Most activated carbon works best at neutral pH levels and moderate temperatures. Extreme conditions can reduce adsorption capacity. Third the contact time between activated carbon and wastewater. Longer contact time allows more pollutants to be trapped so wastewater treatment systems are designed to ensure sufficient mixing and retention. For example a municipal wastewater plant extended contact time from 30 to 60 minutes and saw a 20% increase in pollutant removal efficiency.

Real World Cases of Activated Carbon in Wastewater Treatment

Practical cases show just how efficient activated carbon is in wastewater treatment. A brewery in Henan used granular activated carbon for treating its process wastewater. The wastewater contained high levels of organic matter and had a strong odor. After treatment COD removal reached 90% and the treated water could be reused for cleaning reducing water consumption by 30%. Another case is a printing and dyeing factory that used powder activated carbon for decolorization. Before treatment the wastewater was deeply colored with high COD levels. Adding powder activated carbon at a dosage of 500mg/L reduced color by 98% and COD by 85% making the water safe for discharge. A chemical plant dealing with phenolic wastewater used coal based granular activated carbon in a fixed bed system. The treatment achieved 92% phenol removal ensuring compliance with strict environmental regulations. These cases prove that activated carbon is highly efficient in various wastewater treatment scenarios.

How to Maximize Efficiency in Wastewater Treatment

To get the most out of activated carbon in wastewater treatment follow these practical tips. First choose the right type of activated carbon. For decolorization and quick purification tasks use powder activated carbon. For long term filtration and continuous wastewater treatment granular or columnar activated carbon is better. A textile factory switched from granular to powder activated carbon and saw a 15% increase in decolorization efficiency. Second optimize the dosage. Using too little activated carbon won’t remove enough pollutants while using too much is a waste. Conduct small scale tests to determine the optimal amount. Third maintain the treatment system regularly. For granular activated carbon filters backwash periodically to remove accumulated pollutants and prevent clogging. Replace saturated activated carbon promptly to avoid efficiency drops. A wastewater treatment plant that implemented regular maintenance saw consistent removal rates of over 85% for two years.

Advantages of Using Professional Activated Carbon for Wastewater Treatment

Choosing high quality activated carbon from professional manufacturers like Yihang Carbon ensures maximum efficiency in wastewater treatment. Professional manufacturers produce activated carbon with strict quality control meeting ISO9001 and ISO14001 standards. Their products have consistent adsorption capacity and reliable performance. For example a chemical plant switched to Yihang Carbon’s coconut shell granular activated carbon and noticed a 12% increase in pollutant removal compared to previous suppliers. Professional manufacturers also offer customized solutions based on specific wastewater characteristics. They have a team of experts who can advise on the right type dosage and system design for your wastewater treatment needs. Additionally buying directly from the factory ensures competitive prices and timely supply reducing operational costs for wastewater treatment.

EN

EN