How to measure adsorption in an activated carbon experiment?

Time : 2025-12-16

Conducting an activated carbon experiment to measure adsorption is a practical way to evaluate the performance of different activated carbon types. Whether you’re testing for air and water purification or specific tasks like decolorization knowing how to accurately measure adsorption ensures reliable results. An activated carbon experiment requires simple equipment careful steps and attention to detail. This article will walk you through the key methods steps and tips to measure adsorption effectively in an activated carbon experiment with real world examples to make the process easier to follow.

Key Preparation for an Activated Carbon Experiment

Before starting an activated carbon experiment to measure adsorption proper preparation is essential. First select the right type of activated carbon based on your test purpose. For gas adsorption tests use honeycomb or columnar activated carbon as they are designed for air purification. For liquid decolorization or purification tests powder activated carbon is more suitable due to its quick adsorption speed. A laboratory testing air purification efficiency chose honeycomb activated carbon while another testing water decolorization used powder activated carbon. Second prepare the target pollutant. For gas adsorption you might use VOCs like formaldehyde or benzene. For liquid adsorption common choices include dye solutions or organic compounds. Third gather necessary equipment such as glass containers sensors balances and stirrers. Calibrate instruments like sensors or spectrometers to ensure accuracy. A university laboratory once skipped calibration in an activated carbon experiment and got inconsistent adsorption data which led to repeated tests.

Common Methods to Measure Adsorption in an Activated Carbon Experiment

There are several reliable methods to measure adsorption in an activated carbon experiment. The gravimetric method is simple and widely used. It involves weighing the activated carbon before and after the experiment. The weight difference indicates the amount of pollutant adsorbed. A research team used this method in an activated carbon experiment with columnar activated carbon and found it adsorbed 0.8 grams of VOCs per 10 grams of carbon. The spectrophotometric method is ideal for liquid adsorption tests. It measures the change in light absorption of the solution before and after adding activated carbon. A food factory used this method to test powder activated carbon’s decolorization effect on sugar syrup and the results showed a 92% reduction in color intensity. The gas chromatography method is suitable for gas adsorption experiments especially for measuring VOCs. An environmental laboratory used it to measure honeycomb activated carbon’s adsorption of benzene and obtained precise concentration changes.

Step by Step Process for a Liquid Adsorption Activated Carbon Experiment

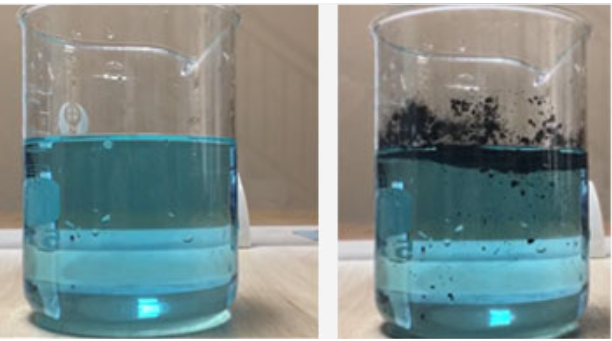

Let’s break down a typical liquid adsorption activated carbon experiment to measure adsorption. First prepare a dye solution with a known concentration for example 100 mg/L of methylene blue. Second weigh 0.5 grams of powder activated carbon (ideal for decolorization) and add it to 500 mL of the dye solution. Third stir the mixture at a constant speed for 2 hours to ensure full contact. Fourth filter the mixture to separate the activated carbon from the solution. Fifth use a spectrophotometer to measure the absorbance of the filtered solution. Compare it with the original solution’s absorbance to calculate the adsorption capacity. A textile factory conducted this experiment to test powder activated carbon’s ability to treat dye wastewater. The results showed the carbon adsorbed 85 mg of dye per gram of carbon meeting the factory’s treatment requirements.

Step by Step Process for a Gas Adsorption Activated Carbon Experiment

For a gas adsorption activated carbon experiment follow these steps. First set up a closed container with a known concentration of a target gas like formaldehyde (50 ppm). Second place 10 grams of honeycomb activated carbon (suitable for gas treatment) in the container. Third seal the container and let it stand for 4 hours ensuring the carbon fully adsorbs the gas. Fourth use a gas sensor to measure the final gas concentration. Calculate the adsorption amount by subtracting the final concentration from the initial concentration. An electronics factory performed this experiment to test honeycomb activated carbon’s VOC removal efficiency. The gas concentration dropped to 8 ppm indicating an adsorption capacity of 42 mg per gram of carbon. This helped the factory select the right carbon for its ventilation system.

Tips to Ensure Accuracy in an Activated Carbon Experiment

To get accurate results in an activated carbon experiment follow these tips. First control environmental factors like temperature and humidity as they affect adsorption. Conduct the experiment at a constant temperature around 25°C. A laboratory once had inconsistent results because the temperature fluctuated during the experiment. Second ensure sufficient contact time. Liquid experiments usually require 1 to 2 hours while gas experiments may need 3 to 4 hours. Third repeat the experiment 2 to 3 times and take the average value to reduce errors. Fourth use high quality activated carbon from reliable manufacturers like Yihang Carbon to ensure consistent performance. A research institute found that using low quality carbon led to unreliable adsorption data in their experiment. Fifth record all data carefully including concentrations weights and time to facilitate result analysis.

Real World Examples of Activated Carbon Experiment Results

Practical activated carbon experiment examples show how adsorption measurement works. A drinking water treatment plant conducted an experiment to test coconut shell granular activated carbon’s adsorption of chlorine. The experiment used the titration method and found the carbon adsorbed 3.2 mg of chlorine per gram of carbon. This helped the plant determine the optimal carbon dosage. An auto repair shop tested columnar activated carbon’s adsorption of paint fumes using gas chromatography. The experiment showed the carbon maintained 80% adsorption efficiency for 6 months. A beverage factory tested powder activated carbon’s adsorption of impurities in fruit juice. The spectrophotometric method revealed a 90% reduction in organic impurities making the juice clearer and safer. These examples prove that a well designed activated carbon experiment provides valuable data for practical applications.

EN

EN