Wastewater Treatment Activated Carbon Blends for Mixed-Chemical Streams

Nature of Mixed-Chemical Contamination in Industrial Wastewater

Industrial wastewater these days is basically a soup of chemicals from all sorts of sources. We're talking about stuff like antibiotics and hormones from pharmaceutical waste, heavy metals such as lead and arsenic, plus those stubborn synthetic compounds like PCBs and PFAS. According to market research published in 2025, around 8 out of 10 treatment facilities are dealing with water containing at least five different contaminants at once. Why so complicated? Well, industries often dump their waste into shared waterways, and then there's the issue of what gets created when manufacturers run their processes. The actual makeup of this polluted water changes throughout the year too, swinging up or down by roughly 23% depending on season, according to studies from 2024. That means water treatment operations need to stay flexible and ready to adjust their methods as conditions shift.

Adsorption Principles in Wastewater Treatment Activated Carbon Applications

Activated carbon removes contaminants through three mechanisms:

- Physical adsorption: Micropores (0.7–2 nm diameter) trap molecules via van der Waals forces

- Chemical adsorption: Functional groups (-OH, -COOH) bind ionic contaminants like Cr(VI)

- Catalytic degradation: Impregnated metals (iron, silver) break down chlorinated compounds

Optimized pore structures achieve 94% VOC removal even at concentrations <50 ppb. The EPA mandates <0.05 ppm for 86 synthetic organics in drinking water, a standard granular activated carbon (GAC) systems consistently meet when properly designed.

Impact of Contamination Complexity on Treatment Efficiency

Competitive adsorption in mixed-chemical streams reduces carbon efficiency by up to 38% versus single-contaminant scenarios. For example:

| Contaminant Pair | Adsorption Capacity Drop |

|---|---|

| Phenol + Methylene Blue | 22% |

| Lead + Humic Acid | 41% |

| PFAS + Nitrate | 55% |

This phenomenon drives custom carbon blend development that combines tailored pore-size distributions with selective surface chemistries to overcome interference.

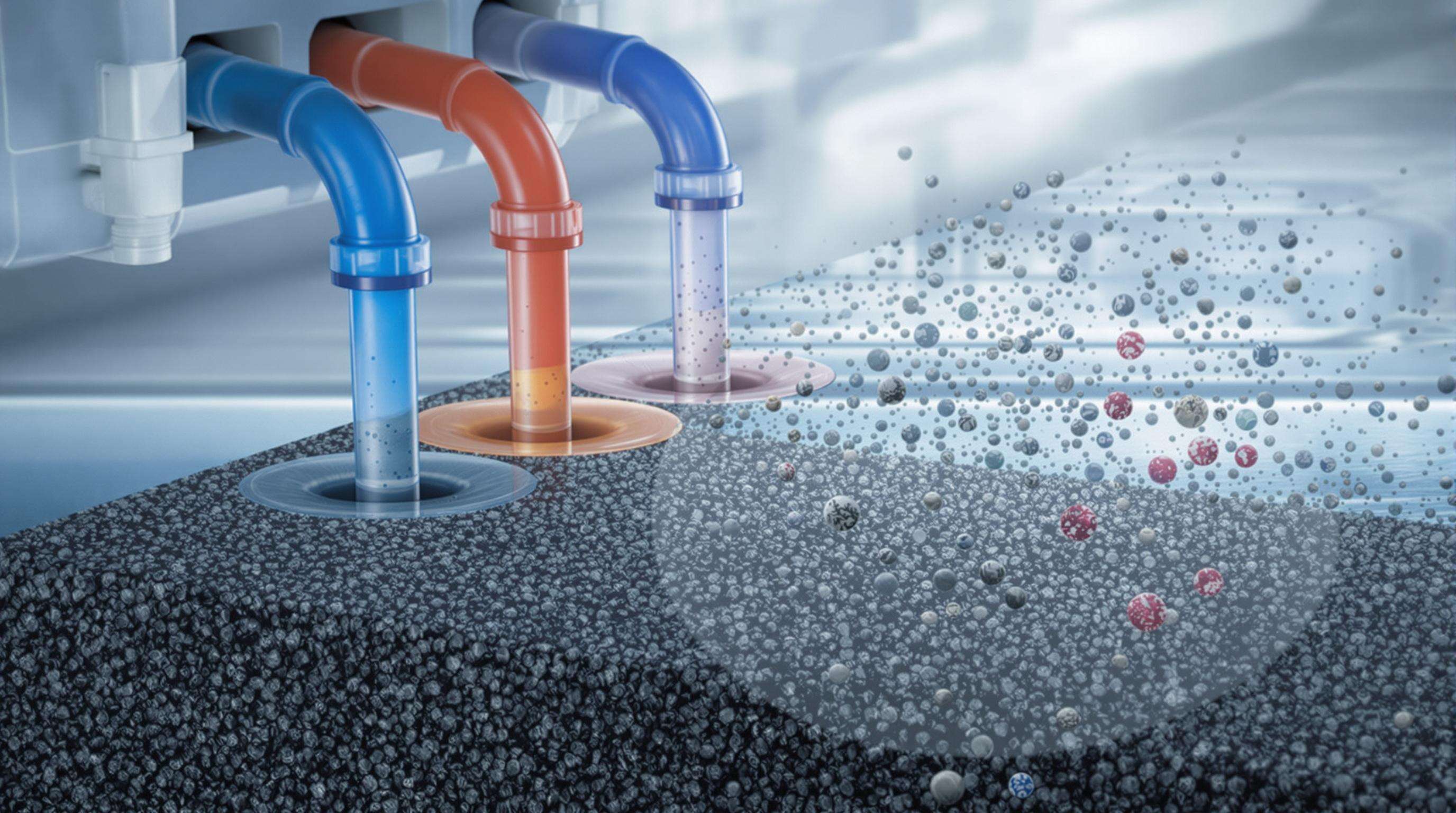

Types of Activated Carbon (PAC, GAC, Impregnated) and Their Functional Advantages

Industrial wastewater streams demand tailored adsorption solutions, with research identifying powdered (PAC), granular (GAC), and impregnated carbons as the primary variants. Each type addresses distinct contamination profiles and operational constraints in wastewater treatment systems.

Powdered Activated Carbon (PAC) for High-Intensity Batch Treatment

The tiny particles of PAC, ranging from 5 to 150 microns, work really fast because they have such a huge surface area over 1,200 square meters per gram. This makes PAC great for handling sudden spikes in contaminant levels during batch treatments. Water treatment plants typically add PAC into their mixing tanks where it can tackle VOCs and those pesky phenolic substances in just about 15 to maybe 30 minutes. What makes PAC so useful is how easily it moves around, letting operators tweak the dosage as needed. And trust me, this matters a lot since the chemistry of incoming water can change completely every single hour at some facilities.

Granular Activated Carbon (GAC) in Continuous Flow Wastewater Systems

Granular activated carbon with those bigger particles ranging from 0.2 to 5 mm works really well in continuous operation fixed bed reactors. These granules last about 60 to 80 percent longer than powdered activated carbon before needing replacement. What makes them so effective is the space between the granules themselves. This creates pathways that trap emulsified hydrocarbons and those stubborn chlorinated solvents even when water flows through at pretty high rates, around 20 gallons per minute per square foot. Most treatment facilities go with GAC because it saves money long term. When systems need to run non stop without frequent shutdowns for media changes, GAC becomes the obvious choice for operators looking to balance performance with operational costs.

Impregnated Carbon for Selective Adsorption in Complex Chemical Mixtures

Chemically enhanced variants integrate metals like iron or silver to target specific contaminants. Sulfur-impregnated carbons achieve >95% mercury removal in electroplating effluents, while potassium hydroxide-treated media adsorb hydrogen sulfide at 10x the capacity of standard GAC. This customization proves vital for pharmaceutical and chemical manufacturing wastes containing competing adsorbates.

Designing High-Performance Activated Carbon Blends for Industrial Effluents

Wastewater treatment activated carbon blends are engineered to address the unique adsorption challenges posed by industrial effluents containing mixed-chemical contaminants. By strategically combining carbon types, these blends optimize contaminant removal while balancing operational costs and system longevity.

Challenges of Competitive Adsorption in Mixed-Chemical Stream Filtration

When multiple contaminants are present in water streams, the tiny pores in activated carbon turn into real-life competitions where different pollutants fight for space on the surface. Research from 2021 showed something interesting about these situations. If there are five or more contaminants mixed together, the ability of activated carbon to grab onto important pollutants actually goes down between 19 and 43 percent because all these substances are competing at once. What we see happening is that smaller molecules such as phenols with molecular weight around 94.11 tend to get into those carbon pores faster than bigger stuff like PFAS which has molecular weights over 500. This size difference creates problems for effective treatment, so engineers have been developing special blends of activated carbons that work better under these complicated conditions.

Synergistic Effects in Blended Carbon Formulations

Modern blends leverage three synergistic mechanisms:

- PAC (Powdered Activated Carbon) provides rapid initial adsorption through its high surface area (900–1,200 m²/g)

- GAC (Granular Activated Carbon) offers sustained removal in continuous flow systems

- Impregnated carbons target specific contaminants like heavy metals through chemical bonding

This multi-stage approach maximizes overall system efficiency by aligning each carbon type with its optimal functional role.

Formulating Blends Based on Feedwater Chemistry and Contaminant Profile

Blend optimization requires:

| Factor | Consideration |

|---|---|

| Molecular weight | PAC for <200 Da, GAC for 200–2,000 Da |

| Charge profile | Cationic modifiers for anionic contaminants |

| Organic content | 1g PAC per 10mg/L COD reduction baseline |

Adjustments based on real-time water analysis ensure peak performance across variable industrial discharges.

Case Study: Optimized GAC-PAC Blend Reduces COD by 68% in Pharmaceutical Wastewater

A European pharmaceutical manufacturer achieved 68% Chemical Oxygen Demand (COD) reduction using a 3:1 GAC-PAC blend in their 5,000 m³/day treatment system. The PAC layer removed 92% of low-MW APIs (atenolol, ibuprofen), while the GAC stage captured high-MW organic byproducts over 14-day filtration cycles–delivering a 33% efficiency gain over single-media systems.

Performance and Longevity of Carbon Blends in High-Load Treatment Environments

Wastewater treatment activated carbon systems require rigorous performance monitoring to maintain efficiency in high-contaminant industrial streams.

Key Performance Metrics for Wastewater Treatment Activated Carbon

Effective carbon blends are evaluated through four parameters: adsorption capacity (mg contaminant/g carbon), hydraulic resistance (measured as pressure drop), bed contact time (optimal 15–30 minutes), and throughput volume before regeneration. Industry data shows optimized blends achieve 80–92% COD removal in mixed-chemical streams when pore structures align with contaminant molecular weights.

Influence of pH, Temperature, and Co-Contaminants on Adsorption Efficiency

According to a study published in 2017 by Barbosa and colleagues in the Journal of Composites Science, extreme pH levels either above 10 or below 3 can cut down on how well activated carbon absorbs phenol by around 34 to 41 percent after about 500 hours of operation. When temperatures go up by just 10 degrees Celsius, the rate at which organic compounds leave the carbon surface speeds up by approximately 18%. Things get even trickier when surfactants or oils are present too. These substances compete for space on the carbon, making it less effective at removing the contaminants we actually care about, with removal rates dropping between 22 and 29 percentage points in such cases.

Regeneration Potential and Lifecycle Management of Carbon Media

Thermal regeneration restores 85–93% of virgin carbon’s adsorption capacity for 3–5 cycles in systems treating <250 ppm TDS streams. Steam reactivation extends service life by 40% compared to chemical regeneration in high-sulfur wastewater applications. Proactive media replacement at 65% capacity loss reduces annual treatment costs by $18–27 per cubic meter in continuous-flow operations.

Emerging Trends: Custom-Engineered and Hybrid Carbon-Based Purification Systems

The wastewater treatment activated carbon sector is evolving rapidly, with manufacturers developing advanced solutions to address increasingly complex contamination profiles. Custom-engineered carbon blends now account for 42% of new industrial installations, reflecting the need for materials precisely matched to specific waste stream chemistries.

Shift Toward Sector-Specific Carbon Blend Solutions

Facilities these days are moving away from those catch-all solutions and going for formulations that actually work best for their specific applications. According to a recent look at the industry in 2023, around two thirds of environmental tech companies have started focusing on carbon blends tailored specifically for different sectors rather than sticking with the old generic stuff. We can see this happening across various industries too. For example, pharmaceutical operations often use amine based adsorption methods while metal finishing shops tend to need media that grabs heavy metals effectively. The results speak for themselves really. These specialized approaches typically show improvements somewhere between 15% to maybe even 40% better performance than what was available before.

Integration of Hybrid Carbon Systems for Enhanced Contaminant Removal

Many modern water treatment facilities are starting to mix granular and powdered activated carbon together in several stages rather than using just one type. This combination takes advantage of what each material does best when it comes to grabbing contaminants out of water. According to some recent research, this mixed system actually removes about 40 percent more stuff from the water compared to setups that only use one kind of carbon medium. The difference is especially noticeable with stubborn organic pollutants and those tricky ionic compounds that don't want to leave. An added benefit? These combined systems seem to last longer too. Studies show carbon beds can stay effective for 25 to 30% longer because the workload gets spread out better between different media types instead of putting all the pressure on one kind of carbon alone.

FAQ: Understanding Mixed-Chemical Streams and Activated Carbon

What are the main contaminants found in industrial wastewater?

Industrial wastewater may contain a variety of chemicals such as antibiotics, hormones from pharmaceutical waste, heavy metals like lead and arsenic, PCBs, and PFAS.

How does activated carbon remove contaminants from wastewater?

Activated carbon removes contaminants through physical adsorption, chemical adsorption, and catalytic degradation. Each method caters to different types of contaminants using pores, chemical bindings, and metal integrations.

Why is customization of activated carbon blends important in wastewater treatment?

Customization is critical due to competitive adsorption that can impede carbon efficiency. Tailored blends help in managing mixed-chemical streams by combining different pore-size distributions and surface chemistries.

What types of activated carbon are used in wastewater treatment?

Powdered Activated Carbon (PAC), Granular Activated Carbon (GAC), and Impregnated Carbon are used as they address specific contamination profiles and operational constraints.

What are the emerging trends in activated carbon systems?

Current trends include sector-specific carbon blend solutions and the integration of hybrid carbon systems that provide enhanced contaminant removal and increased longevity.

EN

EN