Activated carbon pellets are improving the efficiency of gas storage

The Science Behind Gas Storage Optimization

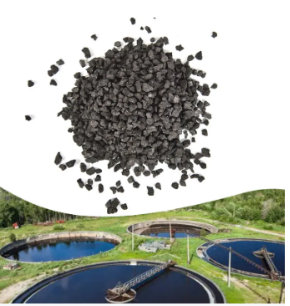

In today's industrial world, finding better ways to store and purify gases is crucial for smooth operations. Activated carbon pellets have become an essential part of the solution, and it all comes down to their unique molecular structure. Picture a sponge, but on a molecular level - these pellets have an incredibly large surface area, often exceeding 1,000 square meters per gram. This vast surface area gives them an amazing ability to adsorb, or "soak up," various gases. In industries where gas needs to be stored and released in a controlled way, traditional materials just can't keep up. They struggle to maintain steady pressure levels, but activated carbon pellets handle these tasks with ease, making them a go-to choice for modern gas storage systems.

Key Advantages for Industrial Gas Management

Industrial procurement managers are always on the lookout for materials that can make their operations run more smoothly and efficiently. Activated carbon pellets offer several distinct advantages that make them stand out. Compared to powdered activated carbon, these pellets are much better at resisting moisture. In high-humidity environments, they hold their shape and structure, ensuring they continue to work effectively. Their consistent size also plays a big role. In gas storage systems, this uniformity creates a steady flow, and field tests have shown that it can reduce maintenance frequency by up to 40%. The activated carbon pellets designed to remove various contaminants also have excellent chemical stability. This means they won't react in unwanted ways with the gases they're storing, which is crucial for keeping the entire system safe and reliable.

Selecting High-Performance Adsorption Materials

When industrial buyers are in the market for materials for gas storage, there are three key factors they need to consider. First is the iodine adsorption value, which tells them how well the material can adsorb small molecules. Premium-grade activated carbon pellets usually have an iodine number above 1,000 mg/g, which indicates they have a well-developed microporous structure. Next is the bulk density. An optimal range of 450 - 500 kg/m³ ensures that the pellets fill storage vessels efficiently without blocking gas flow. Finally, abrasion resistance is important to ensure the pellets don't break down during use. It's also essential to check for third-party certifications that verify the material's composition and compliance with emissions regulations. Meeting these industry-specific requirements is vital for a successful gas storage setup.

Cost-Efficiency in Large-Scale Operations

For procurement professionals responsible for making bulk purchases, the long-term cost of materials is a major concern. Activated carbon pellets offer significant economic benefits over time. Field data shows that in continuous operation, they last 30 - 50% longer than granular alternatives. What's even better is that they can be thermally regenerated, meaning they can be "recharged" and used again multiple times. Over a five-year period, this can reduce replacement costs by up to 60%. In industries that require constant gas processing, like methane purification or hydrogen storage, these efficiency gains translate into substantial savings and a more cost-effective operation overall.

Industry-Specific Application Scenarios

The effectiveness of activated carbon pellets can be seen in various industries. Chemical manufacturing plants, for example, have found that using pellet-based systems has increased their chlorine storage capacity by 18 - 22%. In natural gas processing facilities, specialized pellets have been incredibly successful at reducing sulfur compound contamination by a whopping 93%, all while maintaining the necessary flow rates. Water treatment operators also benefit. When they use pelletized materials in their scrubber towers, they've noticed that biogas purification cycles are 35% faster. These real-world examples highlight just how adaptable and effective activated carbon pellets are across different industrial settings, from chemical production to energy processing and water treatment.

Future Trends in Gas Storage Technology

The future of gas storage technology looks promising, especially when it comes to activated carbon pellets. Current research is focused on creating customized pellet formulations that can target specific gas molecules. This could lead to a whole new level of selectivity in gas separation processes, making it easier to purify and store gases efficiently. There are also advancements in pellet coating technologies on the horizon. These coatings aim to improve the pellets' resistance to oxidation, which would make them suitable for high-temperature storage applications. Industry analysts predict that the demand for activated carbon pellets in energy storage systems will grow by 7.2% each year through 2030. This growth is being driven by the increasing adoption of hydrogen fuel technologies and carbon capture initiatives, showing that activated carbon pellets will continue to play a vital role in the evolving world of gas storage.

EN

EN