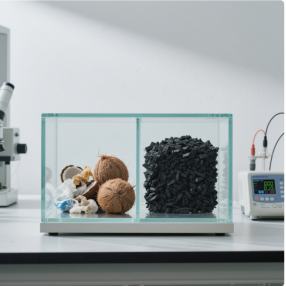

Coconut Shell Activated Carbon or Coal-Based Activated Carbon: Which for Beverage Filtration

Understanding Activated Carbon in Beverage Manufacturing

For industrial beverage producers, choosing the right filtration media is a decision that can make or break their products. It affects everything from how clear the beverage looks to how consistent the taste is, and it's also crucial for meeting regulatory requirements. Activated carbon, with its unique mesoporous structure, is a key player in the filtration process. It works like a tiny sponge, soaking up organic compounds, chlorine byproducts, and elements that can cause unpleasant odors during large-scale production. But when it comes to picking between coconut shell and coal-based activated carbon, producers need to think carefully about how it will impact their operations in bottling plants, breweries, and juice processing facilities.

Key Properties of Coconut Shell Activated Carbon

Coconut shell activated carbon is made from the husks of coconuts, which makes it a sustainable choice. What really sets it apart for beverage applications is its superior microporosity. The coconut shell granular activated carbon has a dense network of pores that are just 0.3 - 0.9 nm in size. These tiny pores are perfect for adsorbing low molecular weight contaminants that are common in liquid sweeteners and alcohol distillation processes. Production managers love it because it has a consistent bulk density, ranging from 450 - 500 kg/m³. reduces the frequency of having to replace the filtration media.

Advantages of Coal-Based Activated Carbon

On the other hand, coal-based activated carbon has its own strengths. Steam-activated coal variants have a broader range of pore sizes, from 0.5 - 2.0 nm. This makes them a good fit for facilities that process beverages with more complex contaminant profiles. Their higher iodine value, between 950 - 1100 mg/g, is particularly useful when it comes to removing color from dark-colored liquids like cola syrups or aged spirits. The natural alkaline pH of coal-based activated carbon, which is 8.5 - 9.5, acts as a built-in shield against acid leaching in carbonated beverage production lines. And for plants that handle high-viscosity fluids, the lower pressure drop characteristics of coal-based activated carbon in fixed-bed reactors make it a preferred choice.

Filtration Efficiency Comparison

Independent tests have shed some light on how these two types of activated carbon stack up in terms of filtration efficiency. Coconut shell activated carbon is a star when it comes to quickly removing chloroform. It can achieve a 92 - 97% removal efficiency in just 30 seconds, outperforming coal-based alternatives by 12 - 15 percentage points in these rapid filtration scenarios. However, coal-based activated carbon has its moment to shine, too. During longer contact periods, it can adsorb 18 - 22% more high-molecular-weight pigments. So, beverage manufacturers need to consider their specific needs. If you're running a bottled water plant and your main goal is to get rid of chlorine, coconut shell activated carbon is the way to go. But if you're processing fruit concentrates and need to decolorize the liquid, coal-based activated carbon might be the better option.

Cost-Benefit Analysis for Industrial Users

When it comes to the bottom line, industrial users need to think about the long-term costs. At first glance, coconut shell activated carbon might seem more expensive to buy, but lifecycle cost modeling tells a different story. It can actually save 23 - 28% on annual media costs for every 1,000 liters processed in continuous flow systems. How? Well, it lasts 35 - 40% longer in repetitive regeneration cycles. And when it's time to reactivate the carbon, the coconut shell granular activated carbon can get the job done in 15 - 20% less time compared to coal-based equivalents, which means significant energy savings in thermal regeneration units. Many large-scale beverage corporations have seen a return on their investment in just 8 - 11 months after switching to coconut-derived media for high-volume purification tasks.

Regulatory Compliance Considerations

Both coconut shell and coal-based activated carbon meet the NSF/ANSI Standard 61 for drinking water systems, but there are some differences that matter when it comes to regulatory compliance in the beverage industry. Coconut shell products have a much lower ash content, usually less than 3%, which is really important for manufacturers who need to meet strict mineral content specifications. In Europe, food safety certifications tend to favor coconut-derived carbons because they have almost no risk of heavy metal leaching - with lead levels below 0.001 ppm and arsenic levels below 0.0005 ppm. And if a processing plant is aiming for organic certification, they need to pay attention to the activation method. Steam-activated coconut shells meet the USDA organic processing standards without the need for chemical additives.

Optimizing Filtration System Design

Industrial users don't have to choose just one type of activated carbon. In fact, they can get the best of both worlds by using a multi-stage configuration. Starting with a coal-based carbon bed is a great way to remove larger particulates and color bodies right off the bat. Then, following up with coconut shell media can polish the beverage, getting rid of any flavor-sensitive compounds. This hybrid approach can reduce the total amount of carbon needed by 18 - 25% compared to using just one type of media. To make the most of this setup, process engineers recommend installing real-time TOC (Total Organic Carbon) monitors. These monitors can automatically track when the media's adsorption capacity is running low, allowing for more accurate and timely media replacement schedules instead of relying on fixed timelines.

EN

EN