Pellets Activated Carbon Length Options for Compact Industrial Towers

How Pellet Length Affects Performance in Compact Industrial Towers

Defining Pellets Activated Carbon Length and Its Role in System Efficiency

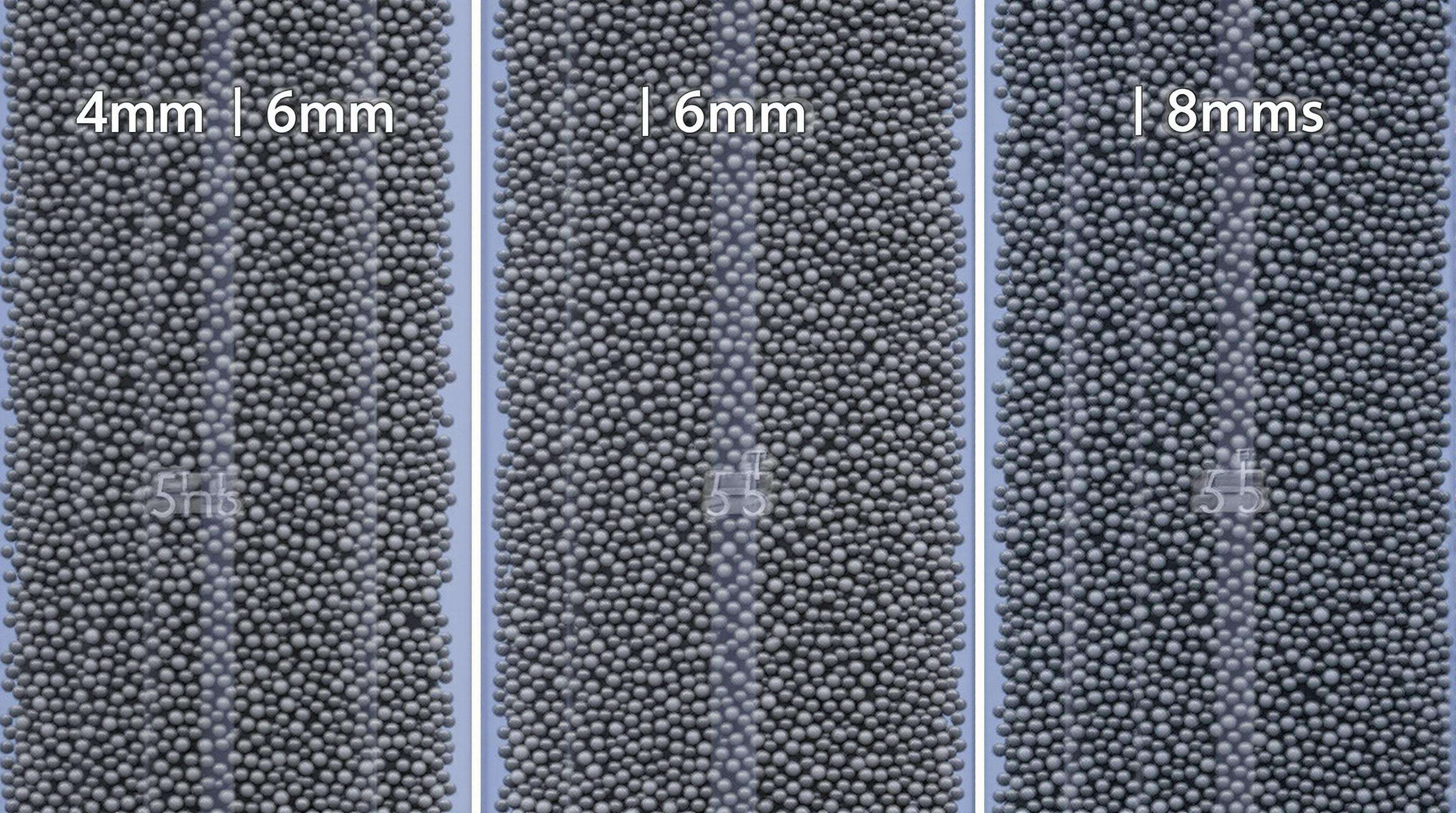

The length of pellets used in activated carbon systems basically means how long these cylinder-shaped adsorbent materials are measured along their axis. Most industrial setups work with sizes between about 4mm and 8mm. The actual length matters quite a bit for how gases interact with the material and how efficiently substances get transferred. Longer pellets, say around 6 to 8mm, actually offer more surface area within the same space, which helps catch more contaminants overall. But there's a catch when dealing with smaller towers where the height compared to diameter is less than 3 to 1. Putting in those bigger pellets can mess up the flow pattern inside, and studies show this might leave roughly 12 percent of the adsorbent material completely unused according to what was found in the Gas Purification Handbook last year.

Impact of Pellet Length on Pressure Drop and Flow Distribution

Pressure drop across carbon beds is strongly influenced by pellet geometry. A recent material science study (MDPI, 2024) found that 6mm pellets achieve the optimal balance in vertical towers:

| Pellet Length | Pressure Drop (kPa) | Flow Uniformity Score |

|---|---|---|

| 4mm | 0.370 | 82/100 |

| 6mm | 0.236 | 94/100 |

| 8mm | 0.291 | 87/100 |

Shorter pellets increase resistance by 56% due to tighter packing, while longer variants are prone to flow channeling. This makes 6mm pellets particularly effective in towers operating at 1.5–2.5 m/s face velocities.

Performance and Design Factors of Activated Carbon Pellets

Three critical factors govern pellet selection:

- Adsorption Kinetics: Shorter pellets (4mm) achieve 22% faster VOC capture in high-flow systems

- Mechanical Stability: 8mm pellets withstand 40% higher shear forces in pulsating flows

- Bed Life Optimization: 6mm pellets demonstrate 30% slower capacity decay in continuous 24/7 operations

The optimal length balances mass transfer efficiency with structural integrity–most compact towers (4–6m height) achieve peak performance with 6mm pellets, maintaining <5% attrition rates over 12-month cycles while achieving 95%+ contaminant removal efficiency.

How Pellet Length Affects Performance in Compact Industrial Towers

Optimal Pellet Length Selection: 4mm vs. 6mm vs. 8mm for Industrial Applications

The length of pellets really matters when it comes to how well they adsorb stuff, what happens with pressure inside the system, and ultimately how much money gets spent running operations. Take 4mm pellets for instance they work pretty fast because they have this great surface area relative to their size. But then there are those 8mm ones that actually help prevent problems with uneven flow distribution in towers that aren't very tall compared to their width. Most folks in the business stick with 6mm pellets as a sweet spot. According to some research from Adsorption Technology Review last year, these standard size pellets manage to utilize about 82% of available space between them, which is significantly better than the 74% seen with those smaller 4mm options. This difference might seem small on paper but translates into real cost savings over time for plant operators.

Comparative Analysis of Common Pellet Lengths in Tower Systems

| Pellet Length | Pressure Drop (Pa/m) | Bed Life (Months) | Ideal Tower H:D Ratio |

|---|---|---|---|

| 4mm | 320–380 | 8–10 | ≥ 3:1 |

| 6mm | 240–290 | 12–14 | 4:1 to 6:1 |

| 8mm | 180–220 | 10–12 | ≥ 7:1 |

Case Study: 6mm Pellets Deliver 30% Longer Bed Life in Vertical Towers

A 24-month field trial with vertical gas scrubbers showed that 6mm activated carbon pellets maintained 95% VOC removal efficiency for 14 months–30% longer than 8mm equivalents. This performance correlates with their optimized pore structure and resistance to premature saturation in turbulent flows.

Matching Pellet Length to Tower Aspect Ratio and Flow Dynamics

Towers with ≥4:1 height-to-diameter ratios achieve 18% better mass transfer using 6mm pellets, avoiding the excessive pressure drops associated with 4mm media. For compact towers under 3m in height, 8mm pellets help prevent flow maldistribution while maintaining a bulk density of 4.2 g/cm³ for minimal footprint.

Gas Phase Air Purification: Enhancing Efficiency with Proper Pellet Length

Mechanisms of Adsorption in Gas Stream Purification

Carbon pellets work their magic by grabbing onto impurities via surface adsorption, basically trapping molecules inside their porous structure. When it comes to pellet size, longer ones around 8 to 12 millimeters actually make air take a winding journey through the filter media. Studies from the Environmental Protection Agency back this up showing that these longer pellets boost contact time between pollutants and carbon by roughly 15 to 30 percent when compared with their shorter counterparts. This extended interaction matters quite a bit when dealing with volatile organic compounds in factory emissions systems. Many manufacturing plants have found that switching to these longer pellets makes a noticeable difference in how clean their exhaust gases end up being after treatment.

Efficiency Metrics: Breakthrough Time and Adsorption Capacity

Tower performance hinges on two key metrics:

- Breakthrough time: 6mm pellets delay contaminant saturation by 40% versus 4mm pellets in ammonia scrubbing tests

- Adsorption capacity: Uniform 8mm pellets achieve 18g toluene/kg carbon, compared to 12g in mixed-length beds

Optimizing pellet length for target molecule sizes maximizes both metrics. For instance, 1–3nm micropores in 6mm pellets capture formaldehyde 27% more effectively than shorter pellets.

Field Report: 95% Contaminant Reduction in Manufacturing Exhaust Streams

A semiconductor plant reduced solvent emissions by 95% after switching to 6mm carbon pellets in its 1:12 aspect ratio towers. The uniform pellet length minimized channeling, extending bed life to 14 months–a 22% improvement over the previous 4–8mm mix. Operators maintained stable pressure drops below 2.5kPa, ensuring consistent airflow above 12,000 CFM.

These results align with research from the International Journal of Chemical Engineering, which attributes 84% of adsorption efficiency gains to optimized pellet geometry rather than material enhancements.

Industrial Applications and System Design Considerations

Proper selection of pellets activated carbon length is essential for balancing adsorption efficiency with structural demands in industrial towers. Designers must consider both contaminant profiles and tower geometry to maximize system longevity.

Activated Carbon in Industrial Applications: Petrochemicals to Food Processing

Activated carbon pellets find their way into all sorts of industries these days. They help remove benzene compounds from petrochemical emissions, clean up solvent streams in pharmaceutical production, and even tackle odors during food processing operations. According to recent data from an industry applications study released in 2024, around three out of four chemical manufacturing companies have started standardizing their pellet specs throughout their pollution control systems. These manufacturers point to better alignment with EPA air quality regulations as one of the main reasons for this shift toward standardized practices.

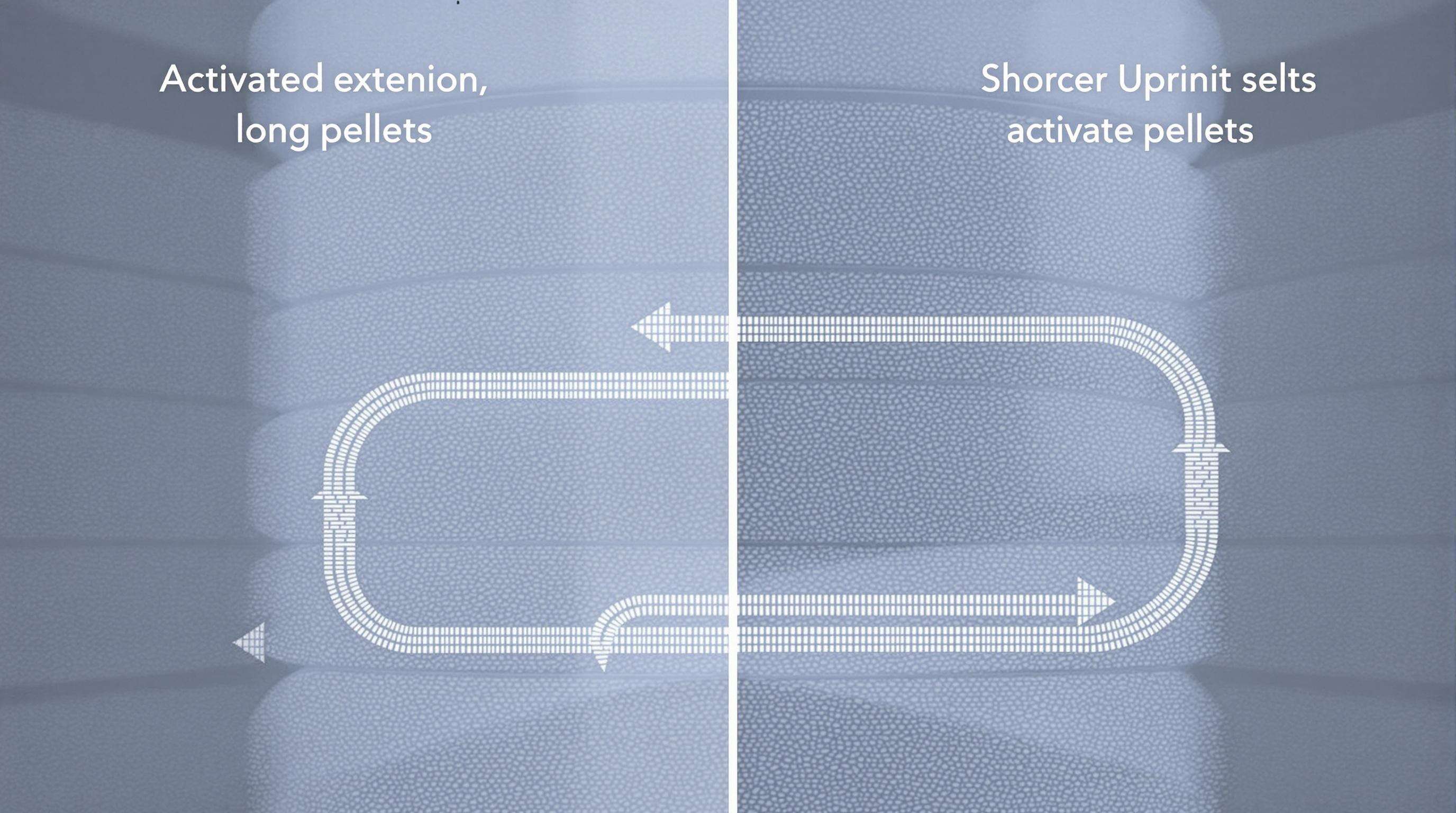

Design Strategy: Minimizing Channeling with Uniform Pellet Length

Keeping pellets at consistent lengths matters a lot for engineers trying to stop channeling issues, which happen when gases find easier routes through the media instead of passing evenly. When systems use pellets that vary about 0.3mm in length, they tend to show around 23% fewer problems with pressure drops compared to setups with uneven media sizes. This becomes really important in tall towers where the ratio of height to diameter goes over 5 to 1. These kinds of installations face bigger challenges with getting proper flow distribution throughout the system, making uniform pellet sizes essential for maintaining efficiency.

Use of Activated Carbon in Industrial Towers: Integration Best Practices

- Loading protocols: Automated filling with vibration settling achieves 92% bed density consistency, outperforming manual methods

- Monitoring parameters: Maintain differential pressure (ΔP) below 1.2 psi/ft to prevent particle fluidization

- Maintenance cycles: Replace the top 15–20% of media annually in continuous operations to sustain 95%+ removal efficiency

Tower designers increasingly adopt 6mm pellets as the industry benchmark, balancing low channeling risk with practical handling during media replacement.

FAQ

Why does pellet length affect purification efficiency?

The length of pellets affects how air flows through them and how much surface area is available for adsorption, impacting the efficiency of removing contaminants.

What pellet length is optimal for compact towers?

6mm pellets are often optimal for compact towers, as they balance pressure drops and adsorption efficiency, effectively utilizing space between pellets.

How do longer pellets influence system performance?

Longer pellets typically increase contact time between air and the adsorbent, enhancing adsorption but potentially causing channeling issues in smaller towers.

EN

EN