Bulk Powdered Activated Carbon for Drinking Water Purification with Low Dust Loss

The Science and Application of Bulk Powdered Activated Carbon in Water Treatment

How Bulk Powdered Activated Carbon Enhances Contaminant Removal in Drinking Water

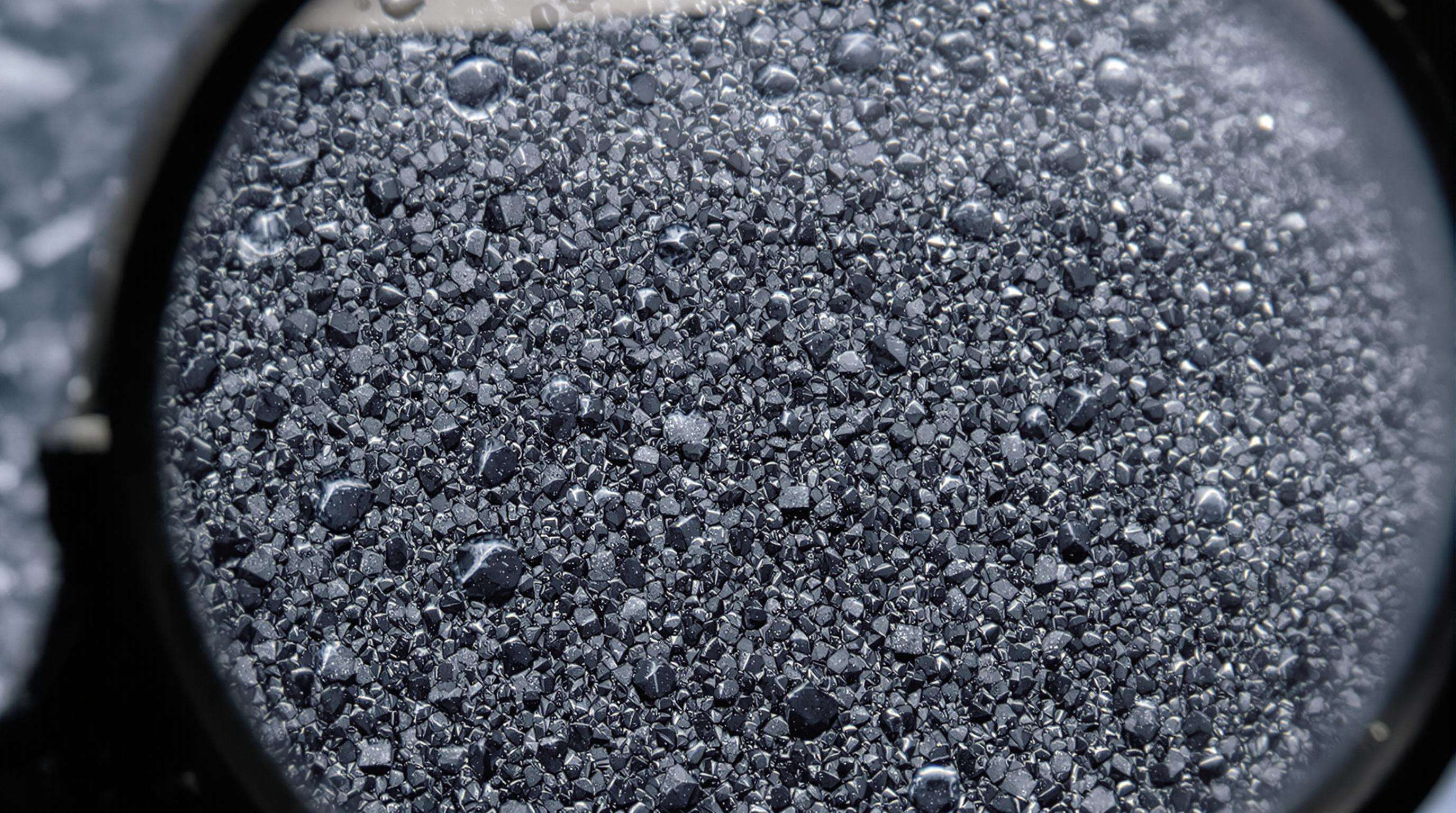

Powdered activated carbon, or PAC for short, works really well because of its tiny pores that grab onto stuff much quicker than those granular versions we see elsewhere. The surface area is pretty impressive too, somewhere around 1200 square meters per gram according to recent studies. This means PAC can catch all sorts of nasty organic pollutants at a molecular level including things like pesticides, drugs from medicine, and those pesky disinfection byproducts. Water treatment plants that put PAC into their sedimentation basins before everything else have seen removal rates hovering between 94% and nearly 100% when dealing with volatile organic compounds. That makes PAC particularly useful when there's sudden contamination issues needing quick fixes.

Key Advantages of PAC in Liquid Phase Purification: Surface Area and Adsorption Kinetics

Due to its sub-25 µm particle size, PAC provides up to three times more adsorption sites per gram than granular activated carbon (GAC). This fine particle morphology enables:

- 92% faster kinetic uptake of taste- and odor-causing compounds like geosmin and MIB

- Short contact times of 15–30 minutes, compared to 4–6 hours for GAC

- Flexible dosing between 2–20 ppm, adjustable based on real-time water quality

A 2025 liquid phase treatment study demonstrated that PAC reduces chlorine demand by 37% in algae-impacted reservoirs by adsorbing organic precursors before disinfection, minimizing harmful byproduct formation.

Optimal Dosage and Dispersion Strategies for Maximum Treatment Efficiency

Pre-hydrating PAC into slurries at a 1:5 water-to-carbon ratio prevents agglomeration and ensures even dispersion in coagulation basins. Systems achieving <5 NTU effluent turbidity combine:

- Dynamic mixing at 30–50 rpm paddle speeds

- Staged dosing—50% during rapid mix, 50% in flocculation

- Real-time particle size monitoring via laser diffraction

Facilities following these protocols report 18% lower PAC consumption while consistently meeting WHO standards for toxin removal, according to a 2024 AWWA benchmark survey.

Powdered vs. Granular Activated Carbon: Performance, Use Cases, and Selection Criteria

Adsorption Efficiency Comparison: PAC vs. GAC in Municipal Water Systems

Powdered Activated Carbon, or PAC for short, works about 40 to 60 percent quicker than Granular Activated Carbon when it comes to grabbing onto pollutants in batch treatments. Why? Because PAC particles are much tinier, usually under 0.18 millimeters across, and they pack in way more surface area per gram, sometimes over 1,000 square meters worth. That's why PAC is so good at snatching up those pesky volatile organic compounds quickly, which makes all the difference during water emergencies when time is against us. On the flip side, GAC has bigger granules ranging from 0.2 to 5 mm, making it better for ongoing filtration needs where steady performance matters more than speed. While GAC can keep working for weeks straight, it just takes much longer to do the job PAC accomplishes in a flash. Recent research back in 2023 showed how effective PAC really is too. The study found that PAC cut down on trihalomethane precursors by nearly 92% in just half an hour, whereas GAC only managed around 78% after waiting six whole hours. Pretty impressive difference when dealing with urgent water quality issues.

When to Use Bulk Powdered Activated Carbon Over Granular Forms

Bulk Powdered Activated Carbon is the preferred solution when:

- Rapid response is critical, such as during pesticide spills or algal blooms

- Space limitations prevent installation of fixed-bed GAC filters

- Seasonal contaminant fluctuations require flexible, on-demand dosing

PAC’s single-use design eliminates the need for regeneration, making it 23% more cost-effective than GAC for short-term contamination events (Water Treatment Quarterly, 2023). Its ability to disperse widely also enhances performance in large reservoirs with dissolved organic matter.

Case Study: Effective Pesticide and Toxin Removal Using Food Grade PAC

In a small town somewhere in the Midwest, local authorities managed to get rid of atrazine contamination that had been running at around 8.2 parts per billion. They did this by using food grade powdered activated carbon at a concentration of 12 milligrams per liter. Within just 45 minutes, they saw an amazing 98 percent drop in atrazine levels, which is way under the Environmental Protection Agency's limit of 3 ppb. What's more, the water remained at a steady pH throughout the process. The new approach worked much better than older granular activated carbon systems because there was absolutely no clogging issues. And as an added bonus, the amount of sludge produced each year went down by almost 19 metric tons since the system required far less frequent backwashing compared to what used to be standard practice.

Innovations in Low-Dust Loss Powdered Activated Carbon for Safer Handling

The Problem of Dust Generation in Traditional PAC Handling

PAC has such tiny particles (less than 0.18 mm) which is why it works so well for adsorption, but this same characteristic creates problems when handling the material. There's just too much dust generated. A recent study from the Water Quality Association back in 2022 found that about one third of all water treatment plants deal with higher maintenance expenses and health issues among workers because of these airborne particles. The dust makes everything harder - storing, moving around, and even measuring out the right amounts becomes a real challenge for facility managers trying to keep things running smoothly.

Engineering Dust-Suppressed PAC: Coatings and Stabilization Technologies

New stabilization techniques, including polymer coatings and electrostatic agglomeration, reduce dust generation by 60–85% in laboratory conditions while preserving adsorption capacity. A 2023 pilot at a European municipal plant found that coated PAC eliminated valve clogging caused by dust entirely over a six-month period, improving system reliability.

Case Study: Reducing Operational Risks in Water Plants with Low-Dust PAC

A Midwestern U.S. utility reduced worker exposure to airborne particulates by 78% after switching to bulk powdered activated carbon with silica-modified surfaces. The modification also decreased carbon carryover into filters, reducing backwash frequency by 22% and saving $12,000 annually in operational costs.

Emerging Trends in Cleaner, Safer Bulk Powdered Activated Carbon Formulations

Current research focuses on biodegradable binding agents and nanostructured carbons that self-aggregate during transport. Humidity-resistant PAC blends are also in development, designed to minimize dust release in the moist environments typical of water treatment plants.

Sustainability, Compliance, and Environmental Impact of PAC Use

Meeting Regulatory Standards with Food Grade and Recycled Activated Carbon

More and more water treatment plants are turning to bulk powdered activated carbon as they struggle to meet those tough regulatory requirements set by agencies like the EPA. The Maximum Contaminant Levels for things like pesticides need to stay below 0.04 parts per million, and heavy metals are another concern altogether. What's interesting is that today's food grade PAC products actually contain between 20 to 40 percent recycled material from coconut shells or wood waste, yet still perform just as well. These formulations keep their impressive surface area above 1,000 square meters per gram. They also pass all the necessary FDA standards under 21 CFR for substances that come into contact with food indirectly. Plus there's an added bonus: these materials cut down on harmful chlorinated disinfection byproducts by somewhere around 60 to 80 percent according to recent studies from AWWA in 2023.

Global Water Quality Regulations Driving Adoption of Bulk PAC

The stricter PFAS regulations introduced through the EU Directive 2020/2184 and the World Health Organization's new 2024 groundwater standards (which set limits at just 4 parts per trillion) have really pushed up demand for powdered activated carbon. Municipal water systems are seeing about a 17% yearly rise in PAC purchases as they try to stay compliant. Most American surface water treatment facilities, around 90% of them actually, have started incorporating PAC into their processes to comply with the EPA's revised Lead and Copper Rule requirements. These treatment plants typically achieve over 99% removal of micropollutants when using dosages ranging from 10 to 50 milligrams per liter of water.

Reducing Environmental Footprint Through Sustainable Sourcing and Circular Practices

Top suppliers reduce CO₂ emissions by 30% through biomass waste sourcing instead of virgin coal. Closed-loop reactivation systems recover 70–85% of spent PAC, diverting an estimated 4.2 million metric tons from landfills annually. Some utilities now blend PAC with recycled biochar, maintaining treatment efficacy while reducing virgin material use by half.

Green Certifications and Their Role in Supplier Selection for Water Treatment

Municipalities increasingly prioritize PAC suppliers with NSF/ANSI 61 certification and ISO 14001 environmental management systems. Third-party Environmental Product Declarations (EPDs) influence 63% of procurement decisions, particularly for carbon-negative producers utilizing solar-powered activation kilns.

FAQ

What makes powdered activated carbon (PAC) more effective than granular activated carbon (GAC)?

PAC has finer particles and a higher surface area compared to GAC, allowing it to adsorb pollutants much faster. This makes PAC particularly useful during water emergencies or when contaminants need to be swiftly managed.

What are the typical applications for bulk powdered activated carbon?

PAC is used not only for rapid response in contaminant removal during emergencies like pesticide spills but also in situations where space is limited and flexible dosing is required, such as seasonal contaminant fluctuations.

Why is there a focus on low-dust PAC?

Traditional PAC handling results in significant dust generation, which can lead to maintenance problems and health risks. Innovations in low-dust PAC formulations aim to minimize these issues, making the material safer and easier to handle.

How does PAC contribute to sustainability in water treatment?

PAC supports sustainability through the use of recycled materials and circular practices. It helps reduce CO₂ emissions and waste by using biomass waste sourcing and closed-loop systems, all while maintaining high performance in water treatment applications.

EN

EN