Water Purification and VOCs Removal: What You Need to Know

Understanding Volatile Organic Compounds (VOCs) in Drinking Water

What Are Volatile Organic Compounds (VOCs)?

VOCs, or Volatile Organic Compounds, are basically carbon-based chemicals that tend to evaporate pretty easily even at normal room temps. These substances end up polluting our air and water supplies quite a bit. Take benzene for instance, which comes out of gasoline, or formaldehyde that's often found in those industrial resins people work with. What makes VOCs different from regular inorganic pollutants is how they get into water sources. They can come from natural causes but also lots of human activity too. Think about all those industrial waste discharges happening every day plus the runoff from cities after rainstorms. Because of this dual origin, getting rid of VOCs isn't straightforward. Special techniques are needed, stuff like adsorption where materials grab onto the compounds, or oxidation processes that break them down chemically.

Common Sources of VOC Contamination in Drinking Water

Drinking water gets contaminated with VOCs mainly because of industrial waste from places like petroleum refineries, chemicals washing off farms after pesticide applications, and stuff leaking out of everyday items we use at home such as glues or thinner for paint. The problem gets worse when old water pipes start to break down over time. These rusty pipes let harmful VOCs from polluted soil and groundwater sneak their way into city water supplies. Cities located close to factories tend to have about three to five times more VOCs floating around compared to what's found in country areas according to recent EPA findings from last year.

Health Risks of VOC Exposure in Drinking Water

Getting exposed briefly to VOCs like toluene often leads to headaches and trouble breathing, but when someone is around these chemicals for longer periods, the problems get much worse. The organs start taking damage and there's actually a higher chance of developing some forms of cancer over time. Research published last year in Environmental Science and Technology found that people who had been drinking water contaminated with trichloroethylene faced about a 40 percent greater risk of liver issues down the road. Kids and folks with weakened immune systems are particularly vulnerable because these harmful substances build up in their bodies over time. Think about PFAS chemicals - they stick around in the system and can cause all sorts of health problems for those already struggling with their immune defenses.

Core Principles of Water Purification and VOCs Removal

The Science Behind VOCs Degradation and Adsorption

There are mainly two ways to get rid of VOCs these days. One is adsorption where stuff sticks to porous materials like activated carbon. The other approach involves breaking them down chemically through what's called advanced oxidation processes or AOPs for short. Activated carbon works pretty well actually, grabbing VOCs thanks to those van der Waals forces inside its tiny pores. Tests show it can remove anywhere from about 85% all the way up to nearly 99% of common pollutants like benzene and trichloroethylene. When it comes to AOPs, they create super reactive hydroxyl radicals that chew up those stubborn chlorinated VOCs. Systems boosted with UV light have been shown to knock out more than 90% of these compounds in lab settings. Some recent research published in 2024 indicates that mixing both approaches together gives better results too. Hybrid systems that combine regular adsorption with catalytic oxidation cut down on leftover contaminants by around 40% when compared to just using one method alone.

Influencing Factors in VOCs Removal Efficiency

Three critical factors determine VOC removal efficiency:

- Carbon pore structure — Micropores (<2 nm diameter) optimize adsorption of small VOC molecules

- Oxidation potential — Hydroxyl radicals (+2.8 V) are more effective than ozone (+2.07 V) at breaking carbon-chlorine bonds

- pH stability — Activated carbon loses 22–35% efficiency in water with pH <6, as shown in 2023 membrane studies

Systems using surface-modified granular activated carbon demonstrate 18% longer service life by resisting premature pore clogging.

Byproducts of VOC Degradation, Such as Formaldehyde

Some VOC treatment methods produce intermediate byproducts during breakdown:

| Degradation Method | Common Byproduct | Concentration Range |

|---|---|---|

| Chlorine AOPs | Chloroform | 8–15 µg/L |

| Ozone Oxidation | Formaldehyde | 12–28 µg/L |

| UV/HO Systems | Ketones | 5–18 µg/L |

Optimized contact time (≥30 minutes) combined with post-filtration through catalytic carbon reduces formaldehyde levels below the WHO's 10 µg/L guideline in 94% of treated samples, according to a 2023 water safety report.

Proven Technologies for Effective VOCs Removal

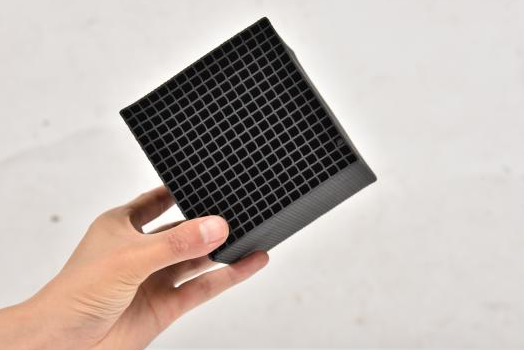

Activated Carbon Adsorption: How Granular Filters Work

Activated carbon remains the go-to solution for removing volatile organic compounds from the air. The process works through physical adsorption as these compounds stick to the massive internal surface area of the carbon material. Quality activated carbon can have anywhere from 500 to over 1,200 square meters of surface area packed into just one gram, making it highly effective at grabbing hold of those stubborn BTX compounds we commonly encounter in industrial settings benzene, toluene and xylene specifically. Regular replacement is essential though, since this ensures the system maintains its effectiveness with VOC reductions typically ranging between 85% and 92%. This makes activated carbon filters superior to many oxidation-based alternatives which sometimes create their own problems by producing harmful byproducts such as formaldehyde during operation.

Advanced Oxidation Processes (AOPs): Hydroxyl Radicals and UV Systems

AOPs destroy VOCs by generating hydroxyl radicals (•OH) through UV light or ozone interactions. These systems eliminate 90–99% of contaminants like trichloroethylene under optimal conditions. However, efficiency drops to 60–75% in hard water due to radical scavenging by calcium and magnesium ions.

| Factor | Impact on VOC Removal |

|---|---|

| UV Intensity | ±15% Efficiency |

| pH Levels | ±20% Reactivity |

| Organic Load | -30% Oxidation Rate |

Air Stripping and Biological Treatment: Biofilters and Towers

Air stripping removes 70–95% of highly volatile VOCs like chloroform by transferring them from water to air in packed towers. Biological filters using Pseudomonas bacteria degrade 60–80% of less volatile VOCs such as MTBE within 12–48 hours, provided conditions remain optimal (pH 6.5–7.5, temperature 20–30°C).

Limitations and Maintenance Challenges in Current Technologies

- Carbon saturation: Filters lose 40% efficiency after 3–6 months

- AOP byproducts: 22% of systems generate formaldehyde exceeding the WHO limit of 0.1 ppm

- Biofilter sensitivity: Temperature shifts >5°C reduce microbial activity by 50%

Regular membrane inspections and pretreatment steps like sediment filtration reduce clogging risks by 65%, extending system lifespan.

Emerging Innovations in Multi-Functional VOCs Control

The field of water purification is advancing rapidly, with integrated systems enhancing efficiency and sustainability:

Nanotechnology and Membrane-Based VOC Removal

Graphene oxide and other nanomaterials enable selective membranes that remove sub-2nm VOCs through molecular sieving. These address key limitations of traditional carbon filters, particularly their poor performance against small, polar compounds like formaldehyde and acetaldehyde.

Hybrid Systems Combining Adsorption, Catalysis, and Real-Time Monitoring

Modern hybrid systems integrate activated carbon with UV-C photocatalytic oxidizers and IoT-enabled VOC sensors. This multi-stage approach allows continuous performance optimization, especially valuable in high-volume industrial settings with fluctuating contamination levels.

Smart Filtration and Future Trends in Sustainable VOC Management

IoT-enabled filtration systems use real-time data to predict filter replacement needs with over 80% accuracy, as demonstrated in a 2024 Scientific Reports study. By optimizing maintenance schedules, these smart systems improve efficiency and reduce unnecessary waste.

Consumer Guidance and Environmental Impact of VOC Removal

Home Water Filtration Systems and Testing for VOCs

When choosing water filters, families would do well to look for ones that actually remove VOCs, especially if they carry the NSF/ANSI Standard 53 certification. These standards basically mean the system takes out at least 80% of certain volatile organic compounds. Most people don't realize this, but a lot of VOCs just can't be tasted or smelled at all, so getting water tested once a year by those EPA approved labs really matters. Something else worth mentioning here is that some filters using oxidation processes might actually produce formaldehyde as a byproduct something that doesn't happen with filters relying solely on adsorption technology for their cleaning action.

Environmental Footprint of Traditional vs. Emerging Methods

Households typically produce around 23 kilograms worth of used carbon waste each year from traditional granular activated carbon systems. Newer catalytic oxidation methods do reduce this waste significantly - about two thirds less actually - though they end up needing roughly thirty percent extra power to run. The latest nanotech membranes have shown impressive results too, taking out nearly all toluene during testing while cutting energy needs by almost half compared to GAC systems. However there remains a problem with scaling these up because manufacturing them creates carbon dioxide emissions at about 1.8 kg per square meter, making widespread adoption difficult right now despite their efficiency benefits.

Scaling VOC Treatment: Challenges and Cost-Sustainability Balance

Looking at treatment on a municipal level shows a pretty big difference in costs between traditional adsorption methods which run about $120 per thousand gallons versus the much pricier advanced oxidation techniques at around $480 for the same amount. There's another option though that sits somewhere in the middle ground. Hybrid biofiltration systems seem to strike a good balance, getting rid of roughly 85% of those volatile organic compounds while costing approximately $260 per thousand gallons. The United Nations released their 2023 Water Security report recently, and it actually suggests that going with decentralized treatment options might cut down infrastructure expenses by nearly a third in rural communities. Even better, these savings don't come at the expense of safety standards since they still meet the Environmental Protection Agency's requirement of keeping VOC levels below 5 parts per billion.

EN

EN